Burn-Off Ovens

Burn-Off Ovens

Process Description

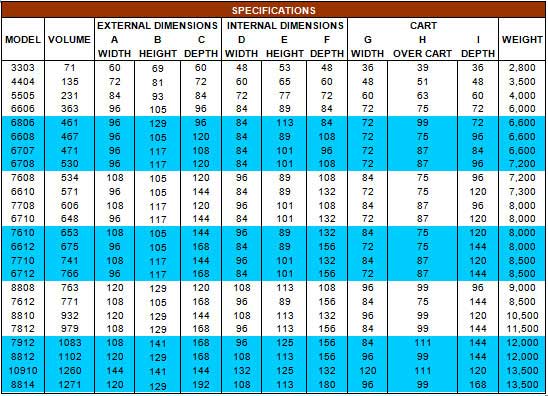

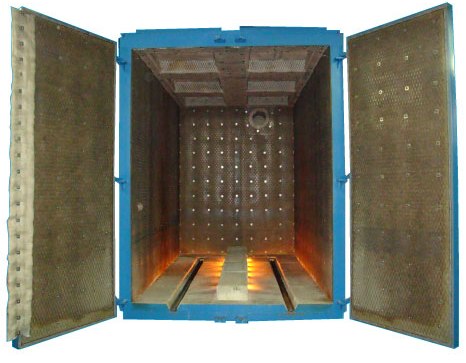

Burn off Ovens are designed to remove combustible material from hooks, racks, fixtures, and parts. Removal of the material is accomplished by heating the substrate to a preset temperature in an oxygen starved atmosphere.The combustible material is reduced to a fine, light ash and fumes. The fumes produced are vented through an afterburner chamber which raises the fume temperatures to 1400F and higher for a minimum of ½ second. The resultant effluent discharged to atmosphere consists of water vapor (H2O) and carbon dioxide (CO2). Ash reduction remains inside the oven and consists primarily of inorganic pigments. Ash is removed from the oven and disposed of in accordance with local codes.

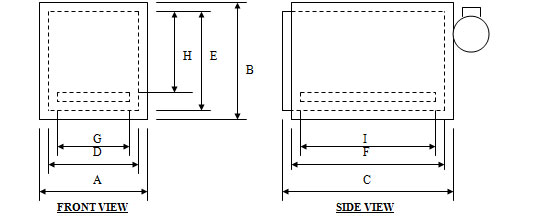

A rear mount afterburner is included with high temperature exhaust stack, roof flashing, weather collar and rain cap. A cart is provided for loading and unloading the oven.

Jackson Oven batch burn-off ovens are user friendly and safe for the environment.

Typical Applications

JOS batch burn-off ovens are designed to remove dry combustible material from hangers, hooks, racks, fixtures, stators, brake shoes etc…….

Typical combustible materials removed by our thermal breakdown process include the following:

- Paint

- Powder Coating

- Epoxy

- Lacquer

- Urethane

- Varnish

- Plastic

- Adhesive

- Rubber & Fiber

- Grease

Other Industries Served

- Engine Rebuilders

- Automotive Part Rebuilders

- Electric Motor Rewind

- Plastic Extrusion

JOS offers modulating gas on both the primary and secondary burner which promotes fuel savings throughout the burn off process. One touch user friendly controls are also incorporated on the batch burn off ovens for ease of use, reducing user error, and lowering the reject rate. The overall design goal is to provide an environmentally safe, use friendly, and cost effective solution to heat cleaning industry.

Options Available

- Battery Back-up

- Special Controls

- Additional Stack

- Stainless Steel Liner

- Installation

- Customized Cart

- Temperature Recorder Before After

- Electric Door Lock

- Extended Warranty

- Start-up & Training