Process Ovens with Afterburners

Jackson Oven Supply Batch Process Ovens with afterburners are designed for applications that involve curing, baking, heat treating, annealing, preheating, drying, and stress relieving in which smoke and/or odor are in the exhaust air stream. Combining the powered exhaust with the after burner make the ovens extremely environmentally friendly.

Temperatures available 500F, 650F & 750.

Afterburner

Our afterburners address environmental violations and promote the good neighbor act. Afterburners are designed to remove smoke and odor from the air stream. The visual smoke and (or) fume smell from a process is vented through the afterburner chamber which operates at 1400 to 1900oF. The resultant effluent discharged to atmosphere consists of water vapor (H2O) and carbon dioxide (CO2), an environmental safe air stream.

The afterburner is integrated with the oven controls to come on first and rise is temperature before the oven heater initiates heat. When the afterburner achieves set point it sends a signal to the oven heater to initiate heat and rise in temperature

Important

If flammable solvents or vapors are present in a Batch Oven, OSHA requires conformance with NFPA 86 which defines Batch Ovens for these applications as Class A ovens. A powered forced exhauster and other non-standard safety equipment must be added. Speak with your representative for clarification and direction.

Standard Features

|

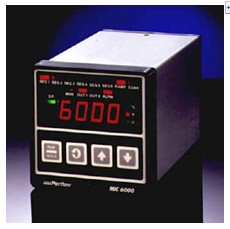

Optional Programmable Temperature Controller

The MIC 6000 is a 1/4 DIN, microprocessor based, single loop, profiling, process controller. It can function either as a basic process controller, utilizing manual set-point changes or it can also execute any one of eight set-point profiles; each profile can have six ramp and six soak segments.

The MIC 6000 is a 1/4 DIN, microprocessor based, single loop, profiling, process controller. It can function either as a basic process controller, utilizing manual set-point changes or it can also execute any one of eight set-point profiles; each profile can have six ramp and six soak segments.

Using the instrument’s security-access mode may restrict access to configuration parameters and set-point.

Optional Temperature Recorder

Designed with the latest innovations in recording technology, enclosures and functionality, the MRC 5000 is slim, trim and simple. The MRC 5000 is a digital circle chart recorder capable of measuring, recording and controlling (optional) up to two process variables from a variety of inputs.

Designed with the latest innovations in recording technology, enclosures and functionality, the MRC 5000 is slim, trim and simple. The MRC 5000 is a digital circle chart recorder capable of measuring, recording and controlling (optional) up to two process variables from a variety of inputs.