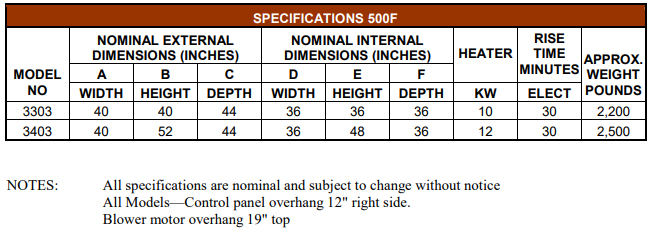

Large Bench Industrial Ovens

4000F / 2040C

Jackson Oven Supply large bench ovens provide solutions for shelf processing a variety of applications including baking, drying, preheating, and curing. User friendly and available in operating temperatures of 400 degrees F.

Standard Features

CONTROLS

- Digital temperature control

- Motor control push buttons

CONSTRUCTION

- Steel interior

- Explosion venting latches

- 2” 8 lb/cf density insulated

- Silicone rubber door gasket

- Incoloy sheathed tubular heating elements

- Two (2) stainless steel shelves

- Stainless steel channel shelves support

- Adjustable fresh air intake and exhaust dampers

SAFETY COMPONENTS

- Excess temperature control, adjustable

- Recirculating blower air pressure switch

- Independent contactors for heating elements

If flammable solvents or vapors are present in a Batch Oven, OSHA requires conformance with NFPA 86 which defines Batch Ovens for these applications as Class A ovens. A powered forced exhauster and other non-standard safety equipment must be added. Speak with your representative for clarification and direction.

Applicable Codes

- NFPA86

- Industrial Risk Insurers

- Factory Mutual

- OSH

Options Available

- Exhaust Fan driven by a 1/8 hp motor with 3” diameter discharge

- Batch timer for setting desired cycle times, oven continues to run

- Programmable temperature controller for programming times and temperatures

- Additional shelves with 50 lb capacity

- Temperature recorder, single pen for recording temperature throughout cycle

- Oven stand to elevate oven 24” working height

- Shut down timer, shuts oven off at end of cycle

Optional Afterburner

An afterburner is available for those customers whose process emits small amounts of smoke, odor and (or) particulate. The fumes from the oven are vented through an afterburner chamber which raises the fume temperatures to 1400F and higher for a minimum of ½ second. The resultant effluent discharged to atmosphere consists of water vapor (H2O) and carbon dioxide (CO2). Afterburner includes high temperature stack, roof flashing, and weather collar and rain cap. JOS will assist with the environmental permitting process.

Optional Programmable Temperature Controller

The MIC 6000 is a 1/4 DIN, microprocessor based, single loop, profiling, process controller. It can function either as a basic process controller, utilizing manual set-point changes or it can also execute any one of eight set-point profiles; each profile can have six ramp and six soak segments.

Using the instrument’s security-access mode may restrict access to configuration parameters and set-point.

Optional Temperature Recorder

Designed with the latest innovations in recording technology, enclosures and functionality, the MRC 5000 is slim, trim and simple. The MRC 5000 is a digital circle chart recorder capable of measuring, recording and controlling (optional) up to two process variables from a variety of inputs.

Designed with the latest innovations in recording technology, enclosures and functionality, the MRC 5000 is slim, trim and simple. The MRC 5000 is a digital circle chart recorder capable of measuring, recording and controlling (optional) up to two process variables from a variety of inputs.

Gas Oven Burner with Electronic Flame Supervision Safeguard.